Sorghum silage: Rising star of dairy feed

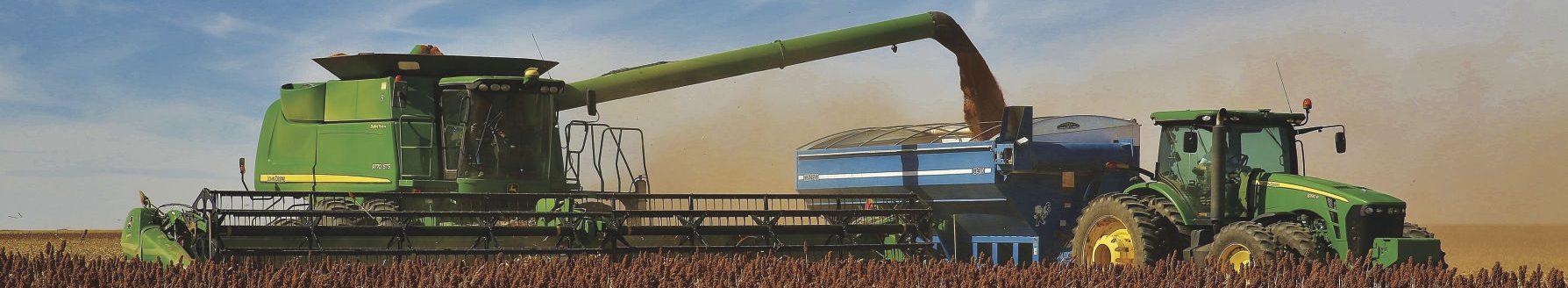

Driving through the heart of dairy country in the High Plains this past summer, one thing became clear—sorghum silage acres are up.

With irrigation water from the Ogallala Aquifer dwindling, dairies and feedyards are searching for more drought-tolerant alternatives to corn. Sorghum is stepping up to the plate.

For years, sorghum silage was primarily used for heifers and dry cows, but now it’s making its way into rations for lactating cows. Dairies are exploring two innovative approaches—male sterile sorghum and advanced kernel processing—to improve feed efficiency. These breakthroughs could redefine how sorghum silage is utilized in modern dairy operations.

Male sterile sorghum: More sugar, less starch

One of the biggest shifts in silage production is the growing use of male sterile sorghum. Unlike traditional sorghum, male sterile varieties don’t produce pollen, meaning no grain is formed in the panicle. The result? Silage with less starch but significantly more water-soluble carbohydrates—essentially, a higher sugar content in the forage.

While research on optimal harvest timing is ongoing, current recommendations suggest waiting four to 10 weeks after heading for direct cutting, or wilting, if needed, to achieve the right moisture levels for ensiling.

A recent dairy trial conducted by Texas A&M specialists Juan Piñeiro and Douglas Duhatschek examined the impact of replacing corn silage with brown midrib male sterile forage sorghum. Their findings were impressive: When 25% of the corn silage in a ration was replaced with sorghum, and inclusion of other feed ingredients was adjusted, energy-corrected milk yield increased by 10%.

Even with a 50% replacement, ECM still rose by 8%. These results suggest that male sterile sorghum could be a game-changer for dairy nutrition.

Breaking barriers with advanced kernel processing and starch availability

One of the most exciting advancements in years in sorghum silage is the development of kernel processing technology specifically designed for sorghum. Traditional processing methods often left sorghum kernels intact, making starch utilization inefficient for livestock. But that’s changing,

thanks to new sorghum kernel processing technology called DurraCut developed by Scherer Inc.

This technology dramatically improves kernel cracking, boosting starch digestibility and maximizing the energy derived from sorghum silage. In another Texas A&M study, rumen in-situ starch digestibility after seven days (isSD7) went from 25.8% to 65.9% starch following an ensiling period of 90 days (see table).

Katie Raver, of Rock River Laboratories, Inc., recently shared compelling data showcasing this breakthrough. In 2024, the lab tested 300 commercial sorghum silage samples for berry (kernel) processing (BPS) using a 2.36 mm screen. The results? An average BPS score of 43%—more than double the 20% average recorded in 2022. Additionally, the starch content of these samples averaged 25%, a significant improvement over previous year.

Looking ahead: a new era for sorghum silage

While laboratory results are promising, the ultimate test will be in real-world milk production. With thousands of tons of sorghum silage harvested using this new processing technology in 2024, the industry eagerly awaits data on how it impacts dairy performance.

As we move into a future where water conservation and efficiency are more critical than ever, sorghum silage is proving to be more than just an alternative—it’s becoming a necessity. With male sterile varieties enhancing digestibility and advanced processing unlocking more energy from each kernel, sorghum’s time has truly come.

Editor’s note: Brent Bean, Ph.D., is the Sorghum Checkoff director of agronomy, Lubbock, Texas. For more information, visit www.sorghumcheckoff.com.