Media, investors see space age farm tech at AGCO expo

When combine operator Josh Murman noticed the bin was nearly full, he tapped commands on a computer screen and set in motion some of the latest in autonomous harvesting technology.

Sitting at attention in a southern Saline County, Kansas, wheat field, a driverless tractor hitched to a grain cart came to life and began motoring toward the huge reaping machine.

During a simulated demonstration in late June on the Clay Ade farm, the grain cart obeyed commands and edged its way alongside the dusty combine, where an auger spout swung out and unloaded.

Once full, the rig peeled off and headed for a grain truck a few hundred yards away. In a real situation, the valuable bounty would be unloaded again and hauled to a grain elevator or on-farm storage.

Another option was sending the tractor/grain cart back to its staging station, to await more orders from Murman, autonomous systems engineer for PTx Trimble of Lincoln, Nebraska, or anyone else at the controls.

The autonomous tractor/grain cart was among the many marvels showcased during 2024 AGCO Tech Day, a joint venture with PTx Trimble and Precision Planting Clarity.

Not far from that demonstration, two spray rigs with electronic eyes combed through fields on search-and-destroy missions for moisture- and yield-robbing weeds. A Precision Planting Vision sprayer, an AGCO subsidiary, installed on non-AGCO equipment rolled through a soybean field.

“It identifies the weed and sprays the weed while leaving the production crop,” said Heath Kehnemund, of Enid, Oklahoma, tactical marketing manager for Massey Ferguson—owned by AGCO—covering Canada and the lower 48 states.

Demonstrating AGCO capabilities in a “green on brown” scenario, a Massey rig, the Trimble Weed Seeker, used both “infrared and near infrared” gear to “identity the green leaf through stubble and fallow ground,” he said.

Herbicides are saved only for the weeds, which cuts chemical consumption and cost.

Those were two of five stations at the show, a yearly demonstration event for national media and investment company officials who trade AGCO investment stock — more than 40 visitors altogether.

“We try to locate different areas around the world to showcase how our products are used in different applications,” said Andrew Sunderman, of Denver, PTx Trimble general manager.

“We showcased in corn, soybeans and wheat this year,” he said.

Visitors to the invitation-only gathering listened to equipment makers talk up their newfangled gear and saw it operate.

“Very seldom do they see the equipment in action. We get people up in the cab, let them operate the machine without the technology and then let them use it with the technology,” Sunderman said. “We’ve been holding a technology day for the past four or five years. They are a way to showcase to folks that we don’t get to work with every day.”

Other stations demonstrated autonomous tractors pulling tillage tools, three precision planters that supply what the seed needs to germinate and grow; and a granular fertilizer monitoring system.

“We ensure a consistent amount of dry fertilizer is applied within the furrow, making sure we have the nutrients readily available to the plant,” Sunderman said. “We want to make sure we get that fertilizer in the best place at the right time, so we can make sure that every dollar of fertilizer we put into the field results in a greater yield for the crop.”

All planting products are available in the marketplace, he said.

AGCO and its associated companies aims to use technology to revolutionize feeding a hungry world, while enhancing the bottom lines of producers.

“The most important asset is the seed in the ground as the crop grows. When it’s time to harvest, the value begins to go down,” said Dinen Subramaniam, PTx Trimble’s senior manager in product management, of Winnipeg, Manitoba. The company also has a team in Lincoln, Nebraska.

The more time it takes, outside of the ideal harvest window, yield and crop qualities are diminished, and “the more money you’re losing,” he said, pitching the equipment under a white tent on the edge of the wheat field.

The autonomous equipment helps curb those losses.

“It’s not really about saving money on labor, or the scarcity of labor,” Subramaniam said. “It’s really the flexibility and availability of labor that we’re trying to address. That’s really where the value comes from with this system.”

Producers rent the digital gear—that can be retrofitted onto most existing equipment or be factory fitted—and they buy subscriptions for hours of service.

“Our approach is different than requiring you to buy a new machine. We have a retrofit first approach,” Sunderman said. “It allows you to install in the equipment you have.”

This is the second year of field testing the autonomous tractor/grain cart, and it’s currently not available to purchase.

“To date we don’t have pricing,” he said. “We’re running with farmers in the field to make sure it’s fully tested and validated before it’s made available for sale.”

Potential benefits the gear could supply from Ade’s 2,100-acre farm are a 5% increase in net farm income from the harvest equipment and an additional 4% using the system for tillage, according to Subramaniam.

PTx Trimble also reported substantial income boosts on two farms in Nebraska and one in Iowa, ranging in size from 900, 1,600 and 3,300 acres, respectively.

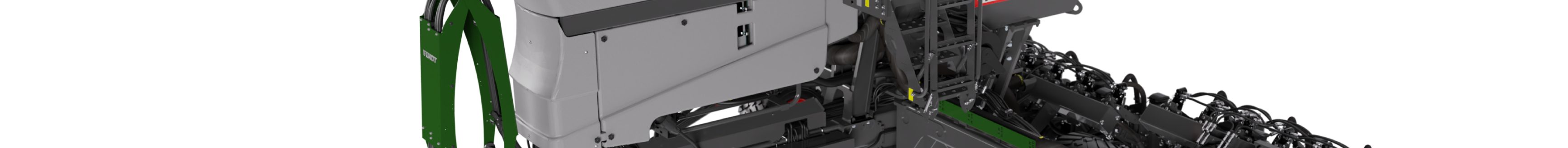

Autonomous tillage products were shown for the first time, Sunderman said. AGCO Tech Day featured a Fendt 900 tractor pulling a Sunflower disc; and a John Deere 8R pulling a Degelman High Speed Disc, using the PTx Trimble technology.

Fendt Momentum Planters, pulled by Fendt tractors, were also on display.

Tim Unruh can be reached at [email protected].