New technology powering sprayer efficiency

From sprayers featuring sensors that identify and douse weeds on-the-go, to unmanned aerial vehicles that apply lower dosages of chemistry, when it comes to killing weeds, the name of the game is efficiency.

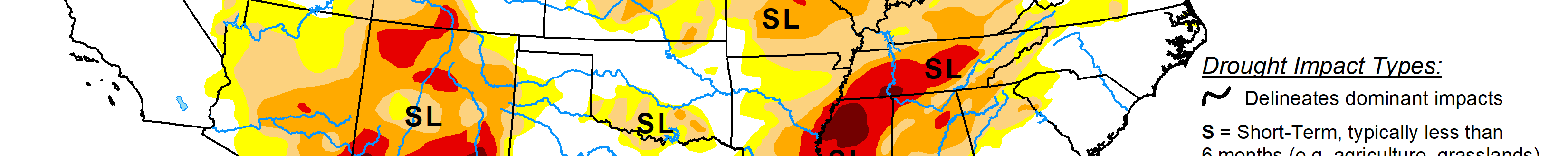

Farmers attending the recent Kansas Ag Research and Technology KAT-CON Event in Manhattan learned how the newest products on the market will make farms more efficient. In the photo taken by Bill Spiegel users of John Deere’s See and Spray Technology spoke during a panel discussion at KATCON 2024. They are: Abe Wiebe, Vulgamore Family Farms, Scott City; Dietrich Kastens, Kastens Farms, Atwood; Sarah Lancaster, Kansas State University Extension, Manhattan; and Brian Ganske, product and systems specialist, John Deere.

David Greer, director of sales for Greeneye Technologies, shared experience with that company’s selective sprayer system, which uses artificial intelligence, additional learning and a boom equipped with sensors to identify and spray weeds within a field.

Greeneye can be installed on several brands of sprayers. Meanwhile, John Deere’s See and Spray system involves a similar technology setup, but is available only on new and select used Deere sprayers. And finally, Zach Hanner, agronomist with Rantizo, shared how UAVs–or drones–are finding a niche on many row crop farms.

See and Spray brings on-the-go learning

John Deere’s See and Spray uses a network of cameras, processors and artificial intelligence to give growers targeted in-season weed control. There are three systems offered by the company: See and Spray Select, which allows for fallow use and targeted spray using a single tank; See and Spray Premium, which can be retrofitted to 2018 and newer John Deere sprayers, plus See and Spray Ultimate, which adds a carbon-fiber boom and a dual product tank for fallow and in-season use.

Deere’s artificial intelligence algorithms identify weeds as the machines move through the field. There is “green on brown” technology, where green weeds are sprayed versus fallow ground. Or, in some cases, users can subscribe to “green on green” technology, where the algorithms identify weeds in green crop.

“It’s another no-brainer technology for us coming at us, whether it’s auto steer, or section control,” says Dietrich Kastens, who farms near Atwood, Kansas, with his family. “What we found over 3,200 acres over a year or two is about an $8 per acre advantage.”

See and Spray users are subject to additional costs; the company charges $3 per acre for corn; $4 for soybeans and $5 for cotton – above the cost of the equipment.

However, users get automated updates, and as the technology “learns” more it improves application speed, weed identification and efficiency, says Brian Ganske, product and system specialist with John Deere.

Sarah Lancaster, weed management specialist at Kansas State University, says growers will need to do the math to see whether See and Spray is worth the additional cost per acre.

Alex Wiebe, who works at Vulgamore Family Farms near Scott City, Kansas, says See and Spray has changed the work of spraying from a field pass that may require 15- to 20-gallons of product per acre to less than a gallon.

Still, See and Spray cannot replace residual herbicides, which should always serve as a base herbicide program for crops. The technology should be used to complement a robust residual program, Ganske says.

Greeneye is a retrofit for many sprayers

Like See and Spray, Greeneye Technology’s precision spray boom systems use a web of cameras and sensors to identify and spray weeds as the sprayer travels through the field. Unlike Deere; however, Greeneye’s products can be retrofitted to a number of self-propelled sprayers, including 2014 or newer Hagie, Case, New Holland or Deere, Greer said.

The retrofit process requires replacing the existing boom with an aluminum, dual wet boom system, adding a 250-gallon tank for dual-product placement and an extra monitor. Users can run broadcast, Greeneye or both at the same time.

Greeneye cameras take constant pictures as the machine travels, with those images sent to a database that is shared among all customers, improving the weed identification algorithm. Users can travel up to about 12 miles per hour in the field, and the company claims up to 90% of herbicide savings.

There is a proprietary scouting platform users can download to fine-tune herbicide programs, the company says.

“Where we really shine is our artificial intelligence. As you run Greeneye, it will constantly get better. The more you run it, the more it learns,” Greer says. “When you first go out and spray a field, it will say it’s a grass or a broadleaf. The more you go across, it will start breaking down to waterhemp, or kochia. It just gets better and better as you run it.”

Greeneye costs $250,000, including a 120-foot boom, installation and warranty. It has no per-acre fee.

Sign up for HPJ Insights

Our weekly newsletter delivers the latest news straight to your inbox including breaking news, our exclusive columns and much more.

Ag in the air

Rantizo is a drone sprayer firm based in Iowa City, Iowa. It sells several drone sprayers, including DJI’s T10 (2.2 gallon tank); T-30 (7.9 gallon tank) and T-40 (11 gallon tank) and the Guardian SC-1 (20 gallon tank). These machines can spray between 12 and 60 acres per hour, Hanner says.

“We’re now looking at efficiency per acre to be competitive with some other stuff that’s on the market,” he says. “But our goal is not to disrupt. Traditional equipment is really good at what it does. Ground rigs and air tractors have a place and a purpose.

“Our goal is to find where are there missing parts in the season. Are there acres that are not getting applied because we don’t have the right tools? We want to be complementary.”

In most cases, drone applicators will have a fleet of drones so that one machine can be in the air applying product and another is being loaded and the batteries replaced. Learning how to set flight pre-determined flight paths to make flights as efficient as possible is key.

The sweet spot for application rate is between half a gallon per acre to 3 gallons per acre. Swath width ranges from 10- to 40-feet; height is about 9-feet above crop canopy. Coverage at these parameters is excellent.

Rantizo offers a DJI T-40 drone, with four batteries and extra tips, for about $40,000. Whether users need a license depends on the state’s regulatory authorities.

Bill Spiegel can be reached at [email protected].