More than one farmer has aired up tractor tires once and forgotten about them, but that could be costing you money, said Dusty Hininger, sales training manager at Firestone Ag.

Appropriate tire pressure, based on tractor weight and ballast, can save fuel, field compaction and time, Hininger said.

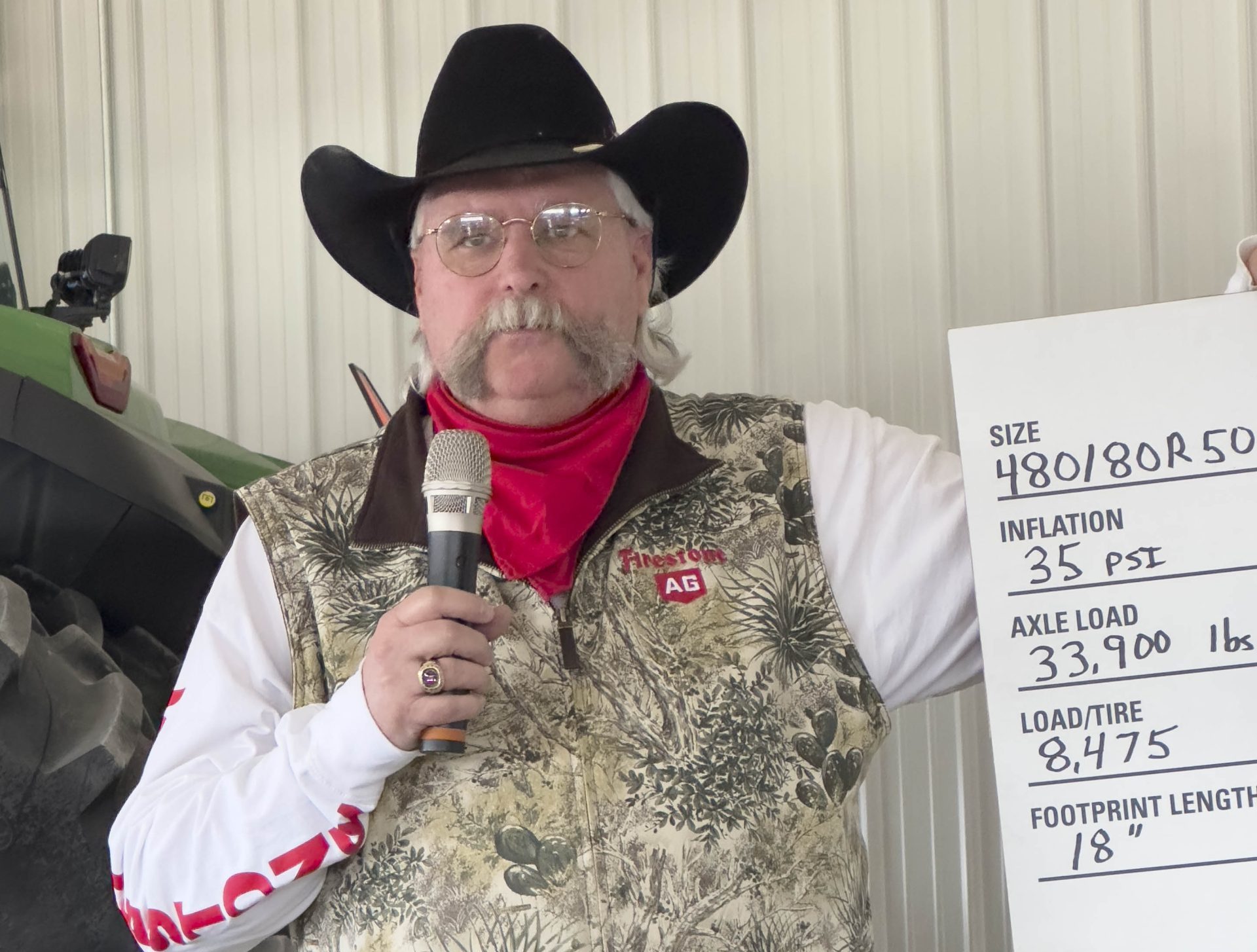

“You have to weigh your tractor, set the air pressure right and make its ballast,” said Hininger, who spoke at a Firestone Ag Tire Clinic near Abilene, Kansas, on March 6, and is pictured above. “If you do this, your tires will last longer.”

Tires are essentially nothing more than “pressure vessels,” designed to hold air and carry a load, adds Greg Jones, global field engineering manager at Firestone Ag. “Air is the key part. Without air, the tires can’t carry the load, and you end up with sidewall damage or tire damage.”

Setting radial tire pressure to the correct pressure—the combination that maximizes tire footprint to achieve maximum traction, yet support tractor weight—is essential.

To air is human

Here’s how to know how much air should be in your tires, Jones said.

- Determine tractor horsepower.

- Weigh each axle after the tractor has been properly ballasted. If fully mounted equipment will be transported, weigh the rear axle with the equipment in the raised position. If liquid manure tanks or grain carts will be towed, add the loaded tongue weight of the equipment to the rear axle weight. Manufacturers can provide loaded tongue weights for their equipment. Determine the weight carried per tire by dividing the axle weight by the number of tires.

- Ballast accordingly.

- Use load and inflation tables available from the tire manufacturer, and inflate tires to the lowest recommended pressure for the weight carried per tire.

- Adjust inflation pressures whenever axle loads change.

You can also determine ideal inflation rate on this website: Inflacalc.FirestoneAg.com.

“Tires are expensive,” Jones said. “Anything you can do to protect that tire to keep from having to replace it, is important. Knowing how to properly set up your tractor and not overloading it, knowing you’ve done everything you can do to protect that tire, is important.”

Additional tire inflation tips

Michigan State University Extension has additional tips to help tractor operators maximize tire efficiency.

- Use a high-quality tire gauge that is easy to read, accurate consistent and graduated in at least 1 psi increments. Gauges designed for use on ATV tires are recommended. Digital, pencil and dial gauges will all work; however, dial gauges tend to be the most easily damaged when dropped.

- Check the inflation pressure often and when the tires are cold, preferably in the morning. Gauge readings can be 1 to 3 psi higher when the tires are warm.

- If fluid ballast has been added to the tires, measure inflation pressure with valve stem in the same position for all tires. Pressures at the bottom of the tire can be 1.5 psi higher than at the top.

- For optimum performance, set all tires on an axle to the same pressure.

Preserving tire life

Today’s high-yielding crops are hard on tires, Hininger said. Stalks of all crops tend to be tougher and thicker than in the past. Factor in drier off seasons, which result in less residue decay, higher cutting angles that make it easier for stalks to puncture tires and taller tires that are less able to knock over stalks, and they all take a toll on tractor tires.

To prolong tire life, Hininger suggested farmers install stubble mitigation equipment on tractors and combines, make passes parallel to the previous year’s rows and avoid installing new tires immediately before or after harvest.

Bill Spiegel can be reached at [email protected].