Iowa Corn growers hail opening of ethanol-to-jet-fuel plant

U.S. Secretary of Agriculture Tom Vilsack was among speakers at the official opening of LanzaJet Freedom Pines Fuels, the world’s first facility to process ethanol into sustainable aviation fuel in Soperton, Georgia.

Vilsack was joined by U.S. Deputy Secretary of Energy David Turk, Georgia Public Service Commissioner Tim Echols, Treutlen County Commissioner Phil Jennings and Soperton Mayor John Koon.

“The Biden-Harris administration is committed to harnessing the full potential of SAF as we continue to build a strong economy that is sustainable, resilient, competitive, and keeps rural places thriving,” said Vilsack. “As we transition to SAF, this will not only create new climate smart commodity markets for American producers, but it will also help American companies such as LanzaJet corner the market of a valuable, emerging industry, while revitalizing rural communities like Soperton with agriculture front and center in the effort. LanzaJet’s facility will help accelerate the SAF industry and provide new economic opportunities for producers for a more sustainable future.”

Pictured above is a corn crop from northeast Iowa.

Plant will create more than 250 jobs

LanzaJet Freedom Pines Fuels is fully funded and has committed offtake agreements for all fuel produced in the next 10 years. Located in Treutlen County, Georgia, less than 100 miles from the port of Savannah, the facility will have created more than 250 total jobs and generate an estimated $70 million in annual economic activity for the local economy.

At a Zoom press conference on the same day, Monte Shaw, executive director of the Iowa Renewable Fuels Association, hailed the plant opening and called the soaring demand for bio-based sustainable fuels an unprecedented opportunity for producers.

Iowa farmers praise development

Dan Keitzer, chair of Iowa Corn Industrial Usage and U.S. Production, said, “SAF is here now and is the best path forward for aviation to reduce its carbon footprint.”

Keitzer said the growing mandate-driven demand for sustainable fuels could help save corn growers from what would otherwise be a major market correction as efficient farmers have produced a massive overhang of corn supplies that has driven prices down. The U.S. Department of Agriculture reported a carryout of 2.2 billion bushels this year, which could increase to 3 billion bushels.

In 1993, Keitzer said, Iowa corn growers were getting yields of 100 bushels per acres; in 2023, those average yields were 177 bushels per acres, almost a doubling—all while using less land than in the 1930s. Producers are outstripping current ethanol demand by 4 to 1, but SAF demand could change the picture. Without SAF demand, the ethanol boom that corn growers have enjoyed for years is winding down as demand from cars and trucks remains flat and climate measures disincentivize internal combustion engines.

Keitzer said the sustainable fuel demand is as important for corn growers as the introduction of the tractor, and added, “We have everything we need to make ethanol-to-SAF happen.”

David Miller, chief economist at Decision Innovations Solutions, spoke on a report his group produced for Iowa corn growers. His team modeled SAF demand into the future, using what he said were conservative assumptions. His group estimated demand growth of 55 million bushels a year, to fuel 12.6 million gallons of new ethanol production.

More plants on the way

The report forecast construction of 63 plants each producing 200 million gallons a year apiece, for new construction totaling $25 billion. Miller said ethanol plants could be bigger to benefit from economies of scale.

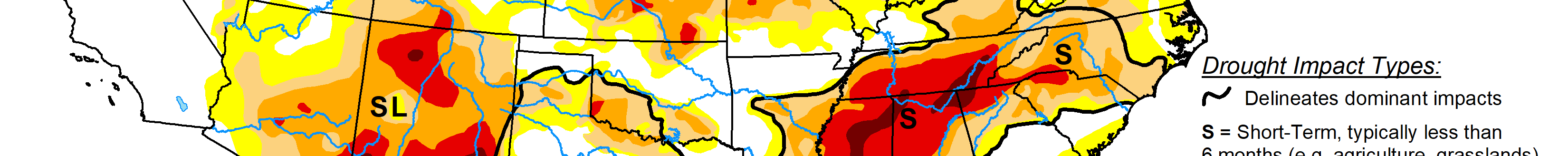

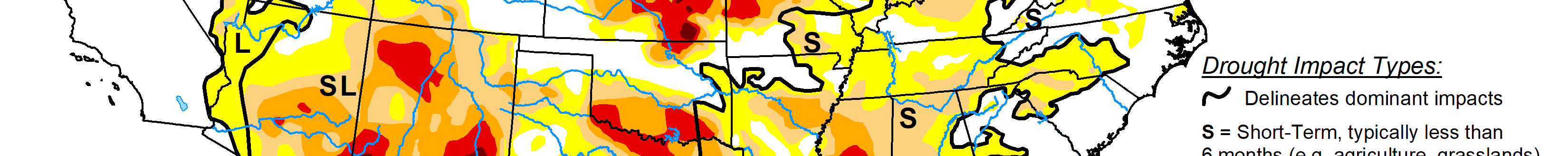

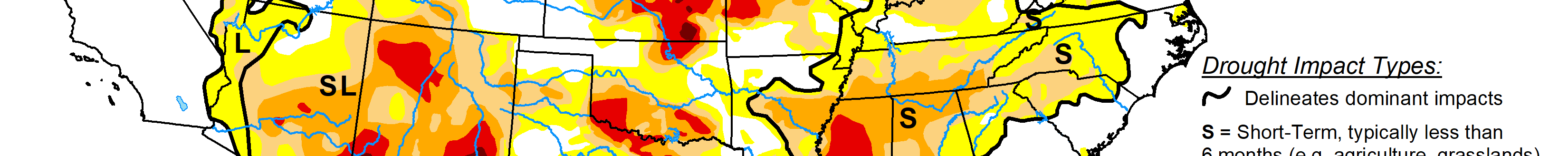

Miller said the current price of corn is $2 a bushel lower than it was 18 months ago, and yield trends are getting stronger—especially in states that got more moisture during the drought, like South Dakota. Yields in northwest Iowa, which got more moisture, were 50% higher than in southwest Iowa.

Miller forecast the building of 11 new sustainable fuel plants in Iowa, 5 of which could be ethanol-to-jet-fuel, and three of which could use the Hydrotreated Esters and Fatty Acids process for refining fats and oils. Some plants can switch from producing SAF to producing sustainable diesel for ground vehicles.

LanzaJet’s technology is recognized as the pioneering ethanol-to-SAF production process and pathway. This ethanol-based technology is the world’s first viable next-generation SAF technology capable of scaling production to the levels needed to decarbonize aviation through widely available and sustainable feedstock, emerging commercial waste-based feedstock solutions, and promising economic conditions.

The plant’s goal is to produce 10 million gallons of SAF and renewable diesel per year from low carbon, sustainable, and certified ethanol which meets U.S. and global standards. Those standards include a production method that has a low carbon intensity score. Ethanol plants currently emit high levels of carbon dioxide in the ethanol-refining process.

All speakers at the press conference agreed on the need to capture and sequester that CO2 to bring down the CI numbers for ethanol. Some foreign sources of biomass, including Brazilian sugar can residues, have a much lower CI score than U.S. corn ethanol. LanzaJet’s technology enables current and future supply volume to support a scaled SAF industry as well as the White House’s SAF Grand Challenge, which calls for a supply of at least 3 billion gallons of SAF annually by 2030 to tangibly reduce aviation emissions.

LanzaJet’s Freedom Pines Fuels plant represents the culmination of a history of firsts within the SAF industry, dating back to its origin in 2010 as the first ethanol to SAF technology to have derived in collaboration with the Pacific Northwest National Lab. The technology’s first commercial flights were completed with Virgin Atlantic and All Nippon Airways in 2018 and 2019, respectively.

“LanzaJet Freedom Pines Fuels is proof of the energy transition accelerating in real time,” said Jennifer Holmgren, LanzaJet board director and chief executive of LanzaTech. “We are demonstrating the ability to establish secure supply chains domestically, create new jobs locally, and produce sustainable aviation fuel globally. This historic facility is an important pillar of a growing SAF economy in the United States and is a significant decarbonization milestone in the world.”

Shaw concluded the Zoom press conference by saying that meeting this need was about business, not politics. “No matter what you think of climate change, at the end of the day, our customers want this. If we don’t take this opportunity, I’m worried about where corn is going. We are lucky that we have a way to avoid that.”

David Murray can be reached at [email protected].