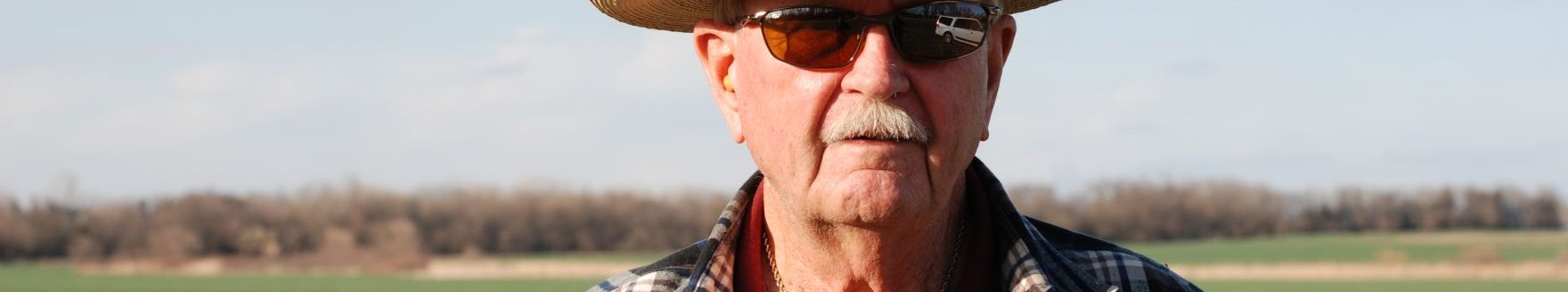

While combines kick up dust as they roll through fields of ripened wheat, Colten Katz is working from sunup to well past sundown to help bin this year’s harvest.

Not that it is a bin buster, he says matter-of-factly. But as a small-town elevator owner, he tries to stay upbeat.

“It could be worse,” Colten said one morning in mid-June, before the day’s action had started. “At least the price is good. That’s the motto—next year will be better.”

It’s not an easy profession—one that is dependent on the weather and prices. However, Colten and his wife, Mandy, are bucking the odds.

Independently owned, single-location grain elevators are an anomaly amid the typical multi-location cooperatives with their tall white skyscrapers. The single-location operations, it seems, have followed the lifespan of the quarter-section farm.

Yet, along Price Street in Turon, Kansas, the Katz family is keeping Turon Mill and Elevator—the nation’s oldest continuously licensed grain elevator—operating. They wouldn’t have it any other way.

A committed customer base and personalized service are among the secrets of their success, said Mandy. These customers are also their friends and neighbors.

“Competition gets tougher every year,” said Colten. “But not everyone wants to go to a place that operates 50 locations.

“I know all my customers,” he said. “I know their kids. We know where they go to school. For us, it’s become a giant family.”

Family tradition

Colten spends his days spraying fields, buying chemicals, watching markets and, this time of year, dumping truck after truck filled with wheat that rumbles across the elevator scales. Mandy oversees the office and manages the books.

Colten said his original plan had been to go to law school in Arizona. He even paid a deposit. Then, a 130-year tradition in the tiny town of Turon came calling.

They took over the business from Mandy’s parents, Ed and Dorothy Marlow. Ed Marlow had suggested putting off law school for a year to give running an elevator a try. That was 2011. By 2019, the couple had purchased the operation.

Wheat harvests at Turon Mill date back at least 130 years. A grain elevator was built shortly after the town was founded in 1886. John R. Price, a pioneer and railroad builder, constructed Turon Mill and Elevator at its current location in 1892. It changed hands a few times and, in 1924, brothers Rex and John Reed operated it with the help of their sons, according to Dorothy Marlow’s research.

During this time, the flour mill produced 150 barrels of flour a day. The Reeds stopped producing flour in 1938 to focus on grain storage. In 1948, after serving in World War II, Bruce Zink and friend O.E. Bedell purchased the elevator. Zink bought out Bedell’s share in the 1960s and continued to expand the operation with the help of his wife, Cleora, and their three daughters, including daughter Connie VanCampen.

Zink’s purchase would begin a legacy that would eventually lead to the Katz family. Zink’s son-in-law Mike VanCampen joined him in 1973. They added chemical, fertilizer and applications to their services and built more grain storage. Zink retired and sold the elevator to the VanCampens in 1980—the same year Mandy’s father Ed joined the business.

“There is satisfaction in running a business that helps family farms, helps the employees you hire,” said Mike VanCampen.

Customers were like family.

Sign up for HPJ Insights

Our weekly newsletter delivers the latest news straight to your inbox including breaking news, our exclusive columns and much more.

“They could look across the fence at Turon Mill and know the boss is there working. And they appreciated that fact.”

In 2003, after 30 years with the business, the VanCampens retired and sold the elevator to longtime employee Ed Marlow. Ed’s wife, Dorothy, joined him to help with the office and bookwork.

“In my mind, and for Dorothy, it was an opportunity of a lifetime for us,” Ed said. “It was an opportunity to buy a business that I already had worked for 23 years. I knew the ins and outs. We decided to take a chance.”

The couple had their own battles trying to keep the business going amid the ever-growing consolidation of Kansas cooperatives. The biggest setback came at the start of harvest on June 6, 2006. A tornado destroyed the mill’s three large bins and the grain dryer and damaged the office.

Ed still gets emotional talking about it.

“I went down there at 3 in the morning and all of a sudden, the lighting cracks, and you see your whole elevator laying flat on the ground. And you think your life is over.”

The elevator family, including the VanCampens, helped pick up the pieces. Customers were patient—some even halting their combines—so the Marlows could bin the crop. Following harvest, they rebuilt Turon Mill to its current capacity of 550,000 bushels.

“One-hundred and thirty years—and all because of a few amazing families,” Mike VanCampen said. “That’s one of the unique things. It is family owned and operated. And it’s one of the few left in the country. It’s amazing to see what Colten and Mandy are doing to keep it going.”

A new generation

Colten and Mandy Katz are now living and breathing the elevator business. Sometimes, that means making special trips after hours or on weekends from their home a few blocks to help their customers.

It’s not unusual for a farmer to knock on their door on a Sunday morning with a small request, Mandy said. That’s just part of the job. They live by the same philosophy as the Marlows and the VanCampens. It’s their duty to provide the quality service needed to help farmers bring in their paycheck.

“They are our livelihood,” Mandy said. “It’s that personalized service that keeps us going. And we will gladly do it. The relationship with our customers, our employees—they are family. It’s the best part of working here.

“We have fantastic employees, there is no way we could do it without them,” Mandy added. “There is no way we could do it without my mom and dad. And I’ve gone over to Mike and Connie’s several times asking for advice. Everyone is still involved.”

Another advantage, Colten said, is being able to react quickly without going through a chain of command. For instance, thinking chemical and fertilizer would be in short supply for the growing season, he purchased two years’ worth of products before prices spiked.

“I knew I wouldn’t be able to buy it in six months, and it is paying dividends today,” Colten said. “Even some of the bigger co-ops are calling me.”

Colten doesn’t regret his change of plans. His family farms and ranches in Edwards County. The lifestyle is a great way to raise a family. Daughters Aubi, 15, and Adde, 9, are now regular helpers during harvest.

“It isn’t about money,” he said. “It’s that my kids can grow up in a small town. Mandy and I get to help farmers. That’s what it is about.”

Amy Bickel can be reached at [email protected].